Build on the same advanced fab infrastructure that powers our own R&D

A little over three months ago, we announced that we’d acquired a small MEMS foundry in North Carolina. Since then we’ve been hard at work integrating our new teammates, orienting ourselves to our new tools, and writing both documentation and a customer ordering interface.

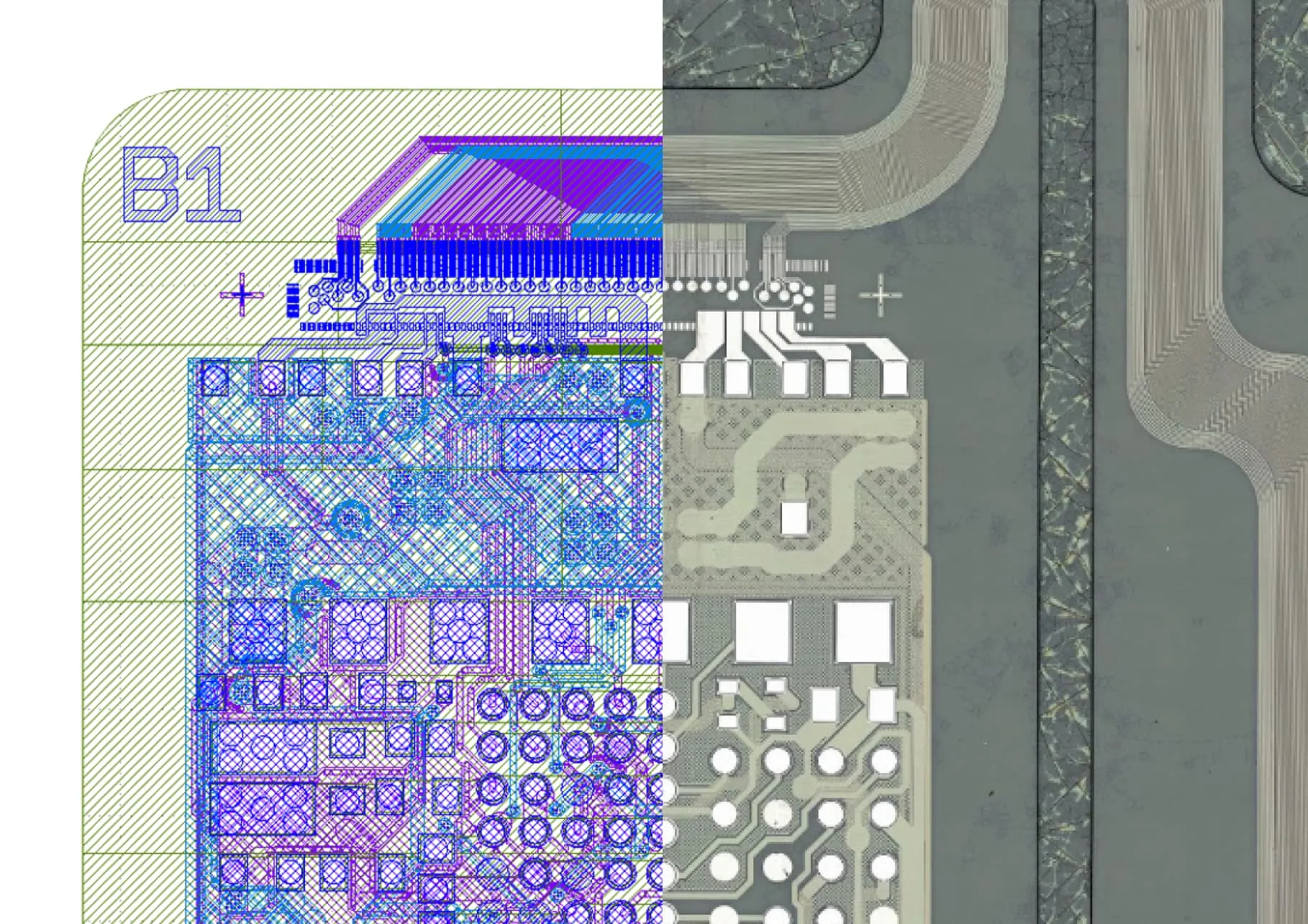

We’ve been soft-launching things as we go, but we are now officially open for business. Since the sophistication of the products we can make depends directly on the tools we have and how quickly we can iterate, we invest heavily in our fab capabilities; our goal with Science Foundry is to enable you to build on this infrastructure, too. In fact, using our public thin-film electrode standard technology it is almost possible to build the Science Lightsheet package substrate! And, of course, we will continue to rapidly improve our process development kits.

This is just the beginning of a very long road for us, and there are still many things to figure out and rough edges to sand down. But the basic parts are all there, and we hope you find it easy to navigate.

Over time, Science Foundry will come to encompass a range of services that we both need to develop our flagship medical devices and which we think we are in a good position to vertically integrate. We operate the MEMS capabilities being announced today as a fairly independent unit, officially known as Science Wafer Services, and which will continue to invest in North Carolina.

Take a look around, and you can always get in touch at foundry@science.xyz if you can’t find what you’re looking for on our website.