Science Foundry allows anyone from academics or startups to large enterprises to build on the technologies we’ve developed in support of our advanced neural engineering technologies. A crucial part of this offering is the MEMS fabrication work done by our team at our facility in Research Triangle Park, North Carolina. MEMS and advanced packaging are an integral part of the medical technologies we develop at Science; accessing these capabilities directly enables the work that we do.

When we started the company, it was immediately apparent that it would be impossible to do the work we wanted to do relying solely on either academic user facilities or existing contract fabs, which either would have pushed us into multi-year iteration cycles or were simply inaccessible for this kind of low-volume work, often with uncommon materials and tool parameters. We had to own this ourselves, and also saw an opportunity to use software to make it feasible to scale and make something available to others that was genuinely differentiated.

Over the last two years we’ve developed a completely new informatics system from the ground up to suit the needs of the many varied demands of our customers, both internal and external. Our goal was to create a software interface for the entire Foundry operation, from the development of new fabrication processes to the delivery of finished products. In this post we’ll take a closer look at two crucial parts of this system: process development and scheduling.

Process Development

Unlike most MEMS providers, Science Foundry specializes in small volume, early-stage process development, providing a valuable middle ground to the self-directed process at a university cleanroom or the production-ready expectations of volume-only foundries. In practice, this means we frequently find ourselves in need of a streamlined interface for planning and developing new processes that captures all of the information required while also enabling lots of flexibility during the development process.

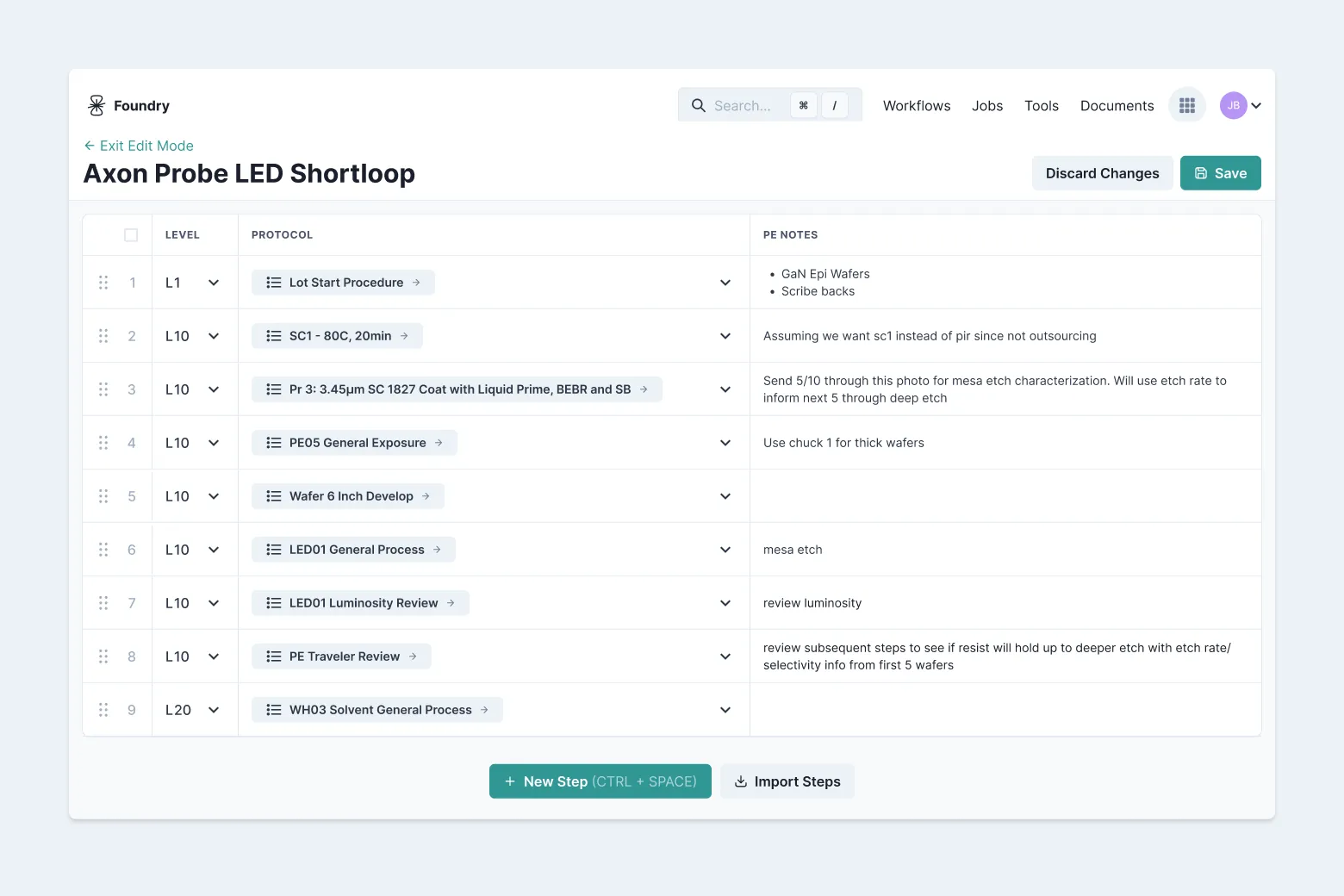

A multi-step workflow in Science Foundry for producing part of our Two-Layer Thin Film Electronics standard technology.

A multi-step workflow in Science Foundry for producing part of our Two-Layer Thin Film Electronics standard technology.

Close collaboration between our software team and our process engineers led us to an interface for building workflows that is optimized for keyboard-driven navigation, allowing our engineers to quickly select and insert one of hundreds of protocols and predefined sequences of protocols.

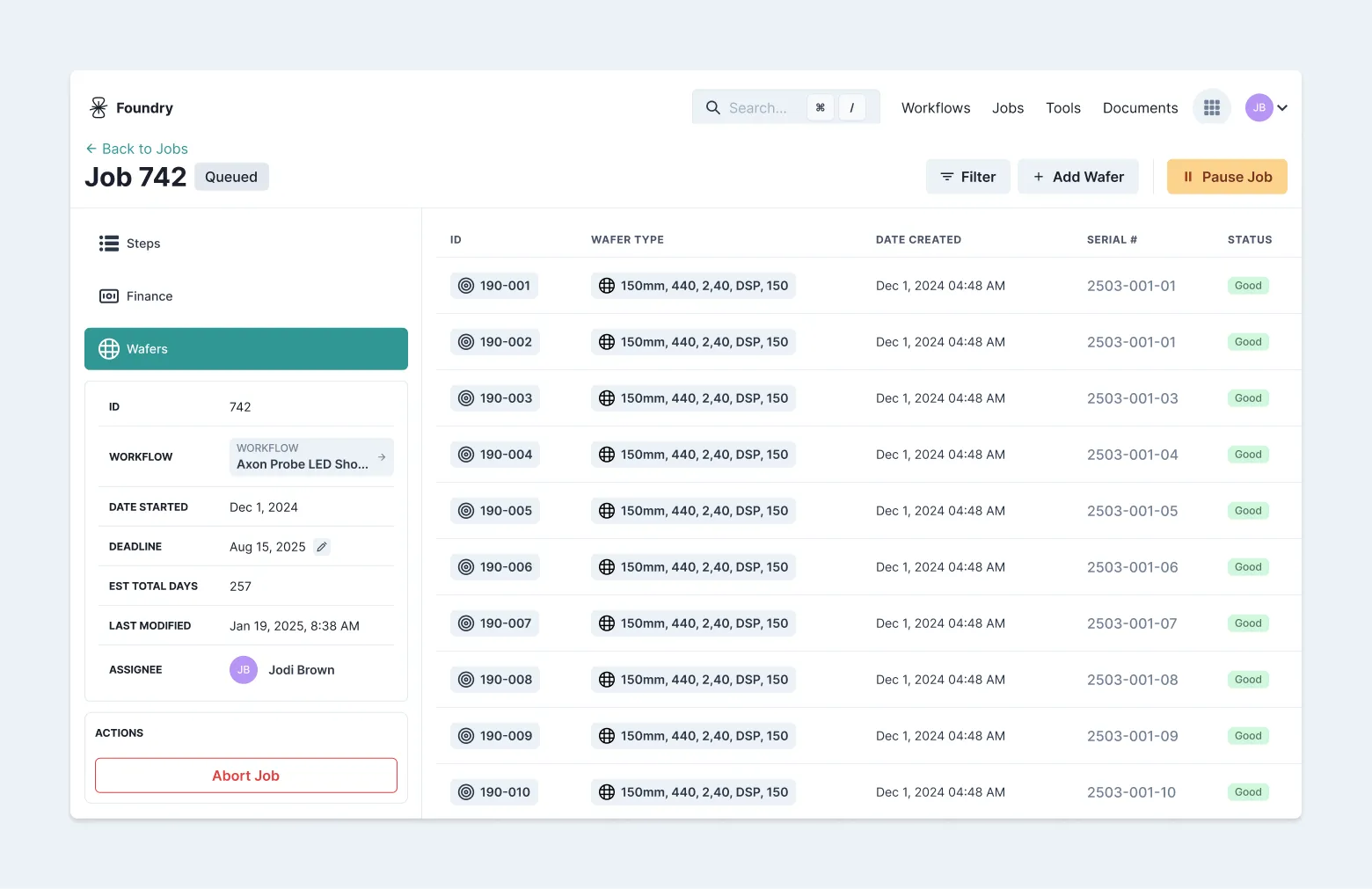

In our system, workflows are made up of a list of steps that are completed on some or all of the wafers moving through the workflow. Workflows allow us to define the steps in our fabrication process from managing inventory levels, through shipping finished products to our customers.

Workflows and the jobs they are associated with are tightly integrated with our inventory management and procurement system, allowing us to trace the history of wafers and other materials from receipt to when they are used.

Workflows and the jobs they are associated with are tightly integrated with our inventory management and procurement system, allowing us to trace the history of wafers and other materials from receipt to when they are used.

Scheduling & Planning

Almost as important as knowing what work to do, is knowing when to do it and when it will be done. If you had a couple tools and a single project to complete, it would be an easy question to definitively answer. But with more than 80 advanced tools, hundreds of distinct protocols, and a mix of development and production jobs each made up of hundreds of separate steps, it can become a practically unsolvable question.

To address this, we developed a scheduling algorithm that ingests the state of the Foundry as it is represented in software, and produces an optimized and feasible list of work to be completed. Broadly speaking, our scheduler also knows about:

-

People: Our experienced technicians cross-train extensively across multiple tools and sectors, further complicating schedule optimization. As part of our tightly integrated quality system, we allow for flexibility in scheduling, while ensuring that people are only assigned work for which they have active training records.

-

Tools: Real-time data on tools, including whether they are fully operational, undergoing maintenance, or pending calibration impacts the work that should be scheduled. Each tool’s unique capabilities, capacity, and supervision requirements are considered.

-

Work: All aspects of the jobs we are completing for customers, such as the steps in the workflows, prioritization, and dependencies alter the schedule. Our scheduler also accounts for less predictable factors such as reworks, send-aheads, the work currently active across the entire Foundry, and how closely each job is trending towards on time delivery.

With this software representation, we utilize sophisticated optimization techniques to improve our productivity and predictability and generate a schedule of work for each day.

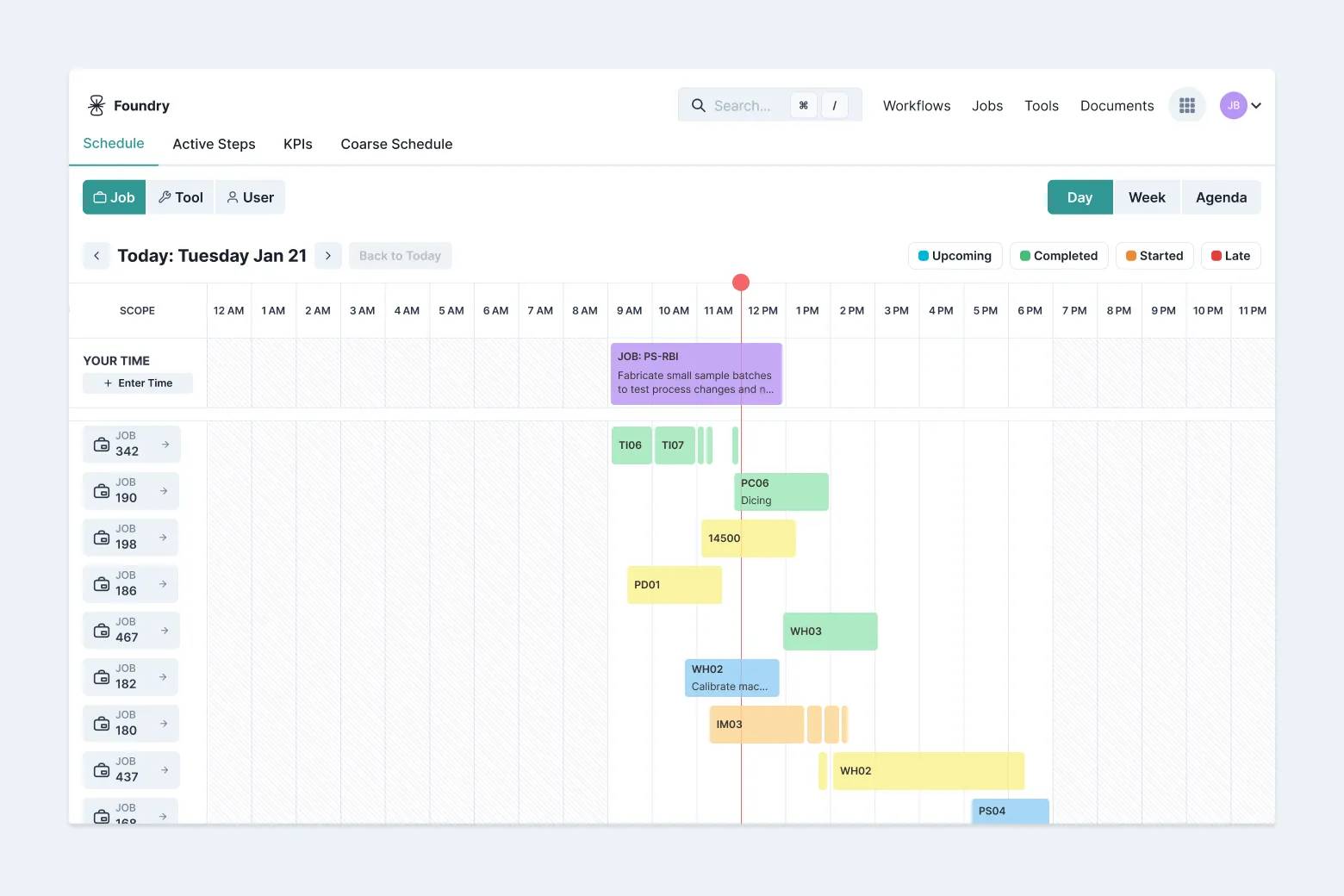

The timeline-based schedule for each day shows the tasks that are planned, started, and completed, as well as allowing engineers and technicians to track other work time.

The timeline-based schedule for each day shows the tasks that are planned, started, and completed, as well as allowing engineers and technicians to track other work time.

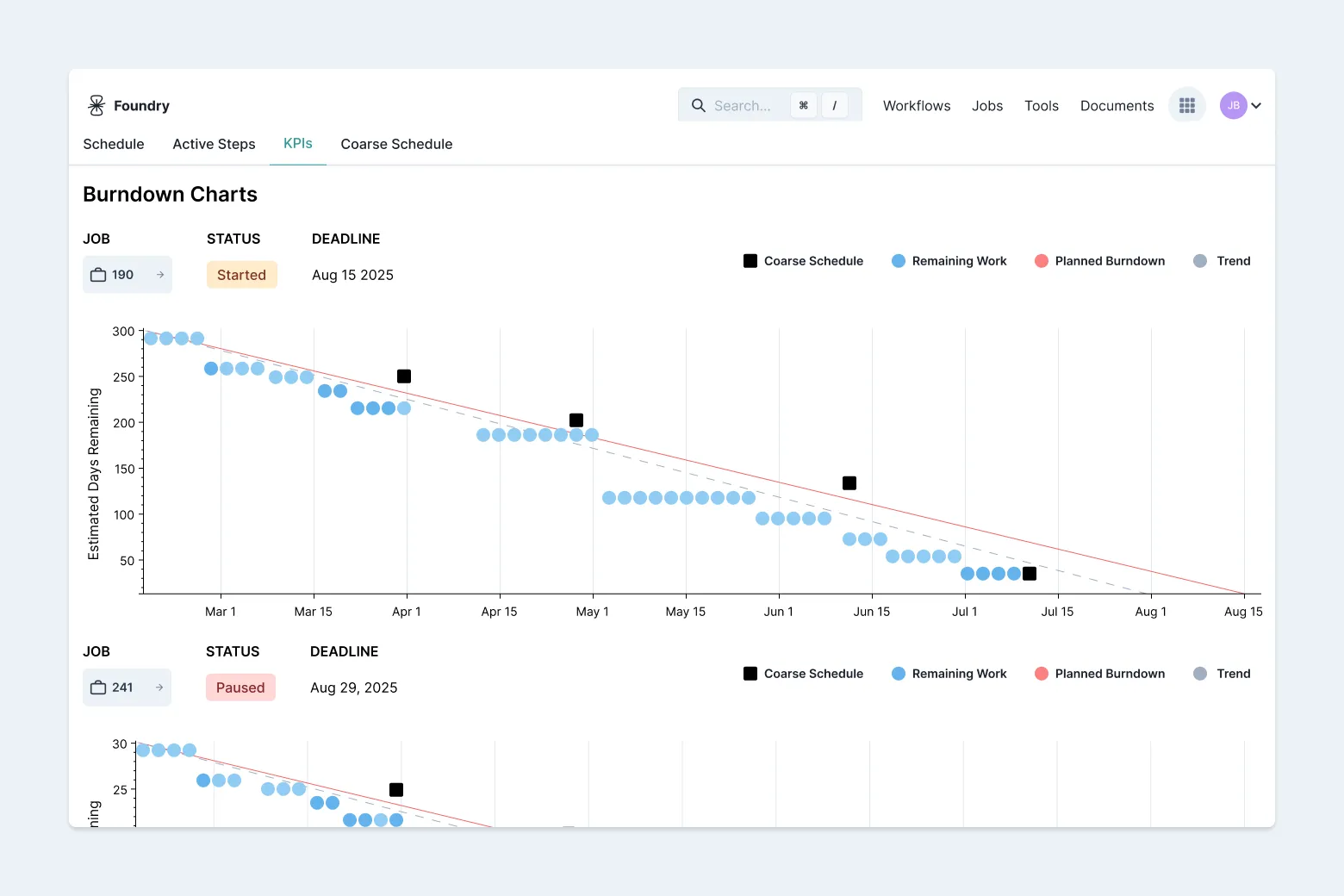

While our scheduler makes a plan for each day, we also automatically monitor how closely each job is adhering to its expected schedule. If it appears like a job might be off track, it is given a higher priority in the daily schedule and prioritized over other work.

This “burndown” chart helps us quickly understand the overall performance and output of Science Foundry. It helps us prioritize tasks to ensure that we are on track to deliver work on time.

This “burndown” chart helps us quickly understand the overall performance and output of Science Foundry. It helps us prioritize tasks to ensure that we are on track to deliver work on time.

Our scheduler supports more than just these day-to-day tactical operations. It also models expected return on improvements from hypothetical changes to any particular part of Foundry operations, like hiring or major capital expenditures. We have relied on this forecasting ability during the planning and building of our expanded microfabrication facilities in North Carolina to ensure minimal disruptions to our processing capabilities as we move tools and personnel.

We’re excited now to see many of these tech investments pay off and make low-run, advanced R&D significantly faster and more economical, for more potential applications.