LPCVD films

Partner with Science Foundry to scale your prototype to production

Science Foundry works with clients across diverse industries, guiding projects beyond the scope of our Standard Technologies from concept to full-scale production.

Our engineers bring specialized expertise and hands-on support to every stage of development, complementing the wide range of advanced tools and capabilities available at Science Foundry. With deep knowledge in material and layer integration, we can create bespoke solutions utilizing non-standard materials rarely available in CMOS foundries—such as gold, noble metals, polymers, piezoelectrics, glass, quartz, III-N semiconductors, and more.

Start a conversation

Production Process Overview

Production Volume

-

Feasibility Review

Review prototype specifications and process flow to determine feasibility in our fab.

-

Development Runs

We collect data, identify issues, and adjust tools as we repeat the production process at least three times.

-

Pre-Production

Process validation at a large scale and any final adjustments before full-scale production.

-

Production

Production of devices at desired volume and schedule based on agreed specifications. 10s to 1000s of wafers.

More than 80 tools spanning broad capabilities

Post processing

Lithography

Polymer films

Dry etching

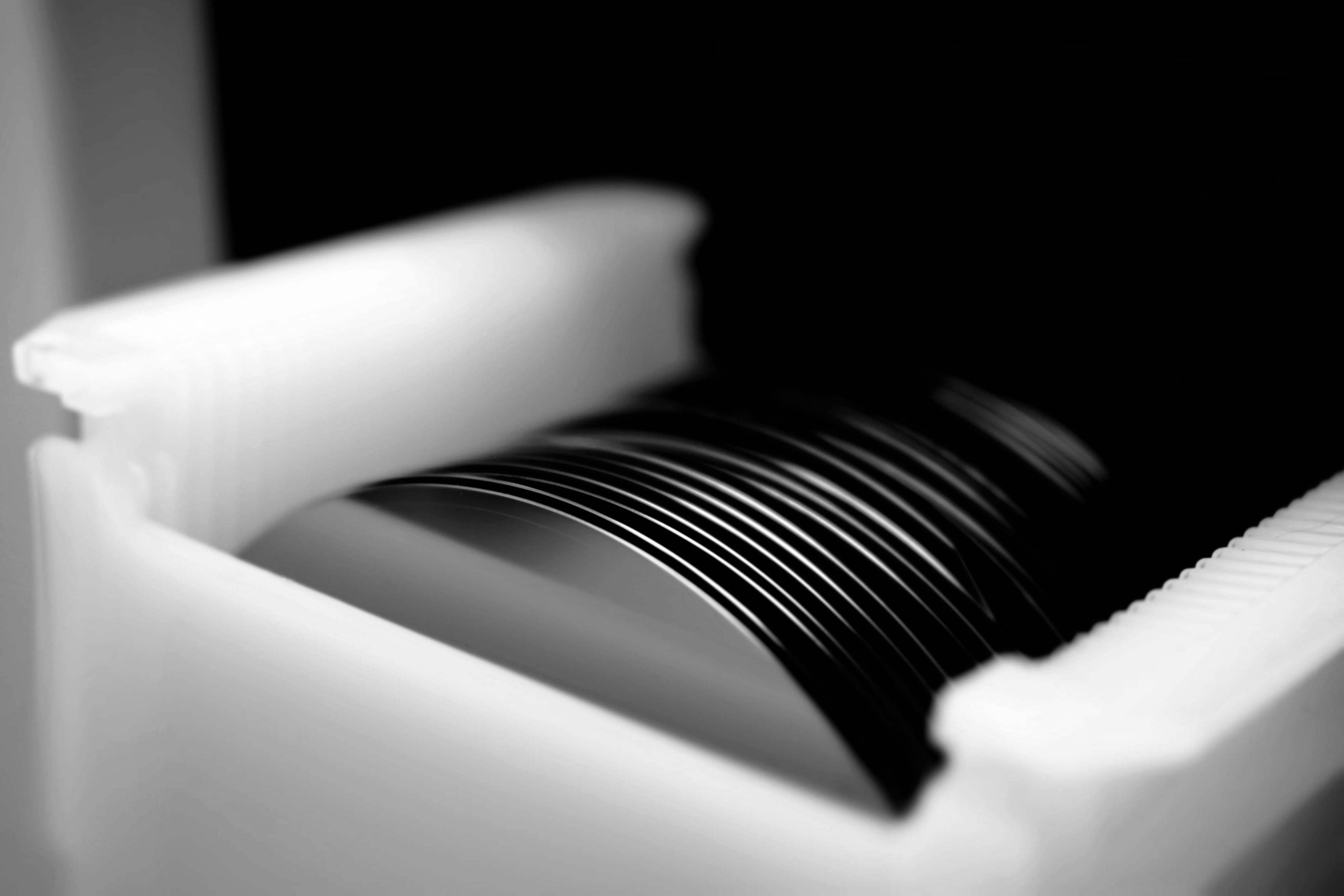

Currently tooled for 6 inch wafer size

Metallization

Wafer bonding

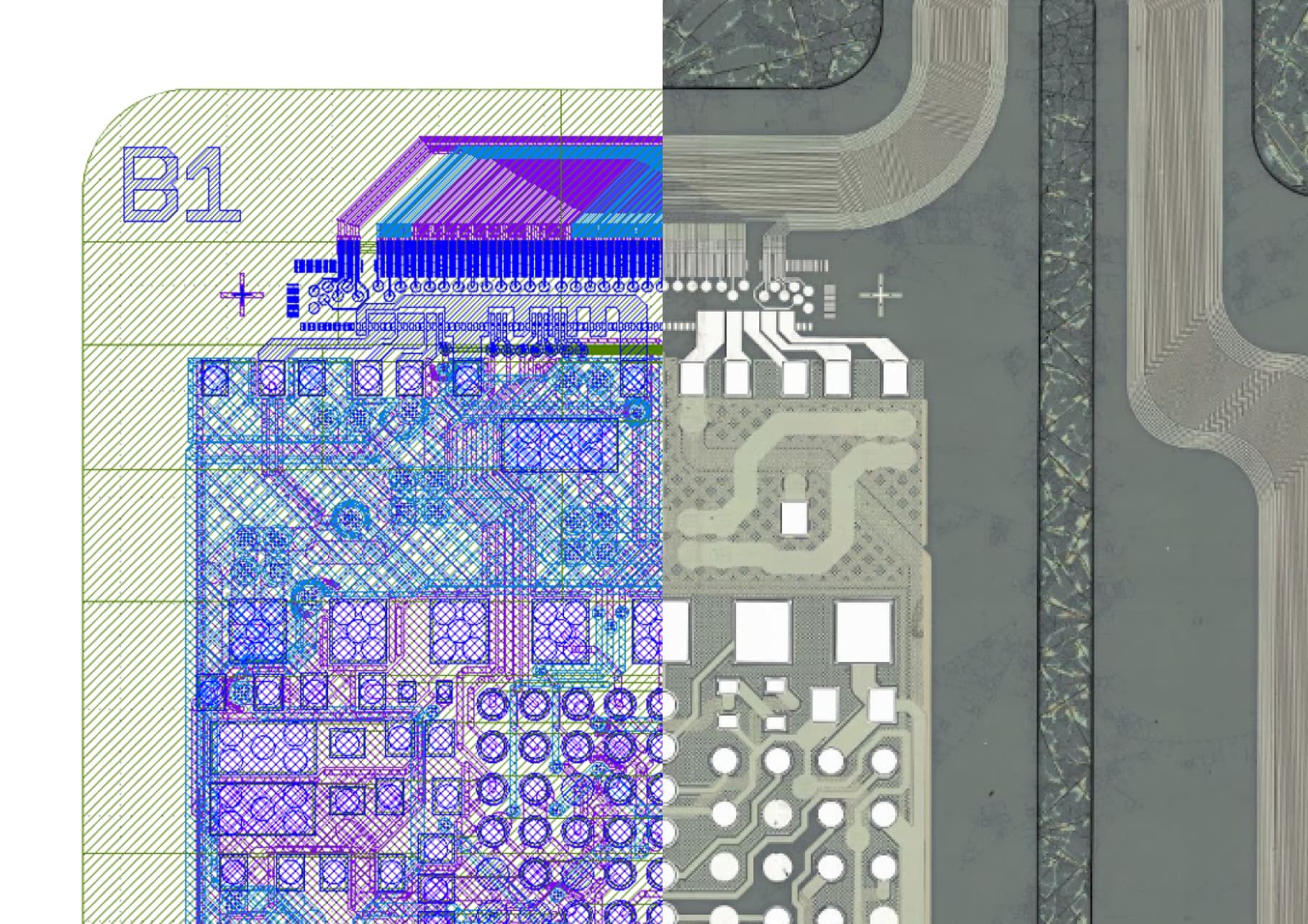

Efficient, software-enabled custom process development

Metrology

Wet Etching

Thermal processing